Professionals

SIO Engineering team is consisting of 10 skilled engineers experienced on the design of high quality steering and suspension parts.

SIO can conduct all steps of reengineering inhouse from OE sample to initial sample, including design and manufacturing of production equipment (machining and assembling apparatus, welding fixtures, forging tools, etc.) and control fixtures, CAD & CAM.

Total 15 employees having 8,4 years of average seniority are working for SIO engineering department.

Know How

SIO has valuable engineering knowledge acquired over the years.

Assesment of the technical knowledge through practical realities formed the basis of SIO's know-how.

Experience +

Marketing Strategy +

Historical Warranty & Quality Data +

Initial Product Trial Feedback +

Market Research and Claims =

SIO Design Guideline + Advanced SIO Design

Experience

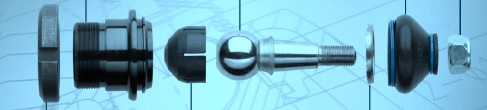

SIO has been designing and producing steering and suspension parts since 1991.

SIO Engineering has been developing new parts for well known brands in the market since the beginning.

SIO Engineering does not only design and develop the steering and suspension parts, but also some test machines and customized unique production machines and equipment which are designed and produced inhouse which are still in use in SIO.

Bushing Ejection Test Machine

Joint Leakage Test Machine

Assembling Press(Software designed)

Design & Engineering Software

Engineering team of SIO has been equipped with all necessary tools and software for easy, better and efficient design.

Advanced high-end 3D CAD/CAM/CAE software Siemens NX9 is being used for CAD & CAM modelling of products and production&control equipment and molding.

ANSYS simulation software enables us to predict how our products will operate in the real world and to address problems and other challenges in a fast, cost-effective, risk-free manner before production.

For higher organizational efficiency and short initial sample leadtime, a unique software system is used for tracking and managing Product Development Planning.

Inhouse Testing Capability

Comprehensive and detailed tests are very important for a successful engineering process. Reliability, quality and long life of the products can only be achieved this way.

Some of these tests which SIO Quality Lab is capable of are listed below.

DIMENSIONAL & VISUAL:

Coordinate-measuring system (CMM): Zeiss Contura, precise measuring system

Optical Dimension Control: High accuracy 3 axis non-contact video measuring system

FUNCTION & PERFORMANCE & DURABILITY:

MTS Landmark® Servohydraulic Test System: Static and dynamic tests — everything from fatigue life and fracture growth studies to tension, bending and compression tests

Performance Test: Axial - Radial Stiffness and Articulation Torque and Rotation Torque

Durability Test: 4 Axis, Axial & Radial +/- Load, Articulation and Rotation

Climate Chamber: Simulation of temperature and humidity conditions

Salt Spray Testing: 480 Lt

Paint and Coating Control: Thickness, Cross-Cut etc..

Other Tension-Bending-Compression Strength Test Machines: MTS Exceed™ 45 Electromechanical Universal Test System, Zwick 5tons

Electronic measuring of torque values

MATERIAL:

Full Spectral Analysis: Low & High Carbon Steel, Sheet Metal and Aluminium

Microstructure Analysis: ASTM Grain Size, Nodularity, Porosity, Decarburisation

Hardness, Surface Roughness, Ballpin Impact Tests

Reengineering Process

Each and every new design (product and process) is being verified and validated.

This will ensure the realibility of the design prior to mass production.

INPUT:

OE sample

Customer Spesific Requirements

Past Problem Reflection

Team Experience

Marketing Strategy

Product / Process Benchmark Data

ANALYSIS OF OE SAMPLE:

Visual, Dimensional, Functional, Performance,Durability

SIO ALTERNATIVE DESIGN:

Comparative Drawing

Initial Design Approval

Process Design (Aparatus, C/F etc.)

Build up initial sample

PART VALIDATION:

Part Validation : Visual, Dimensional, Functional, Performance, Durability

Final Design / Part Approval

INITIAL SAMPLE APPROVAL:

Initial sample approval by Customer

"Green light" for serial production

Cooperation with Third Party Experts

SIO Engineering is in cooperation with some third parties to have external support such as extreme material, system analysis, testing and technical information.

Certification

SIO design and reengineering processes are certified according to ISO 9001 by Breau Veritas accredited by;

DAR (Deutscher Akreditierungs Rat)

UKAS (United Kingdom Accreditation Service)

ANAB (ANSI-ASQ National Accreditation Board)